Another thing that bugged me for a long while was the T16's speakers. It's well known the fronts are not the 4" the likes of Crutchfield and Sonic Electronix insist they are. They're actually 3½" speakers. That's simple enough, I tossed a set of Pioneer TS-A879 speakers at them and called it a day. The rears however are bothersome. Some sites claim they're 4".

They are not.

Some try and claim 5¼" will fit...they don't.

What fits and fits proper? The out of production Polk db501:

These are, in fact, 4T format speakers, which is to say 4½" which nobody freaking makes anymore. The db501s are the last model I could find in that actual size, and they fit perfect. They seal the hole completely, the screw holes all line up exactly right. I tossed in some thin foam tape just to help keep the box sealed. That and some modern speaker batting inside and I am satisfied with my audio. Apart from maybe an under-seat sub someday.

Somehow in the time I have been doing this, my Hella Supertone horns just...up and died. Feed with angry pixies, no happy tooting. So, I decided to go a different route and snapped up a pair of stock UCF20 horns. I just needed to slightly modify my custom horn bracket, extend one horn cable and it all, just, worked!

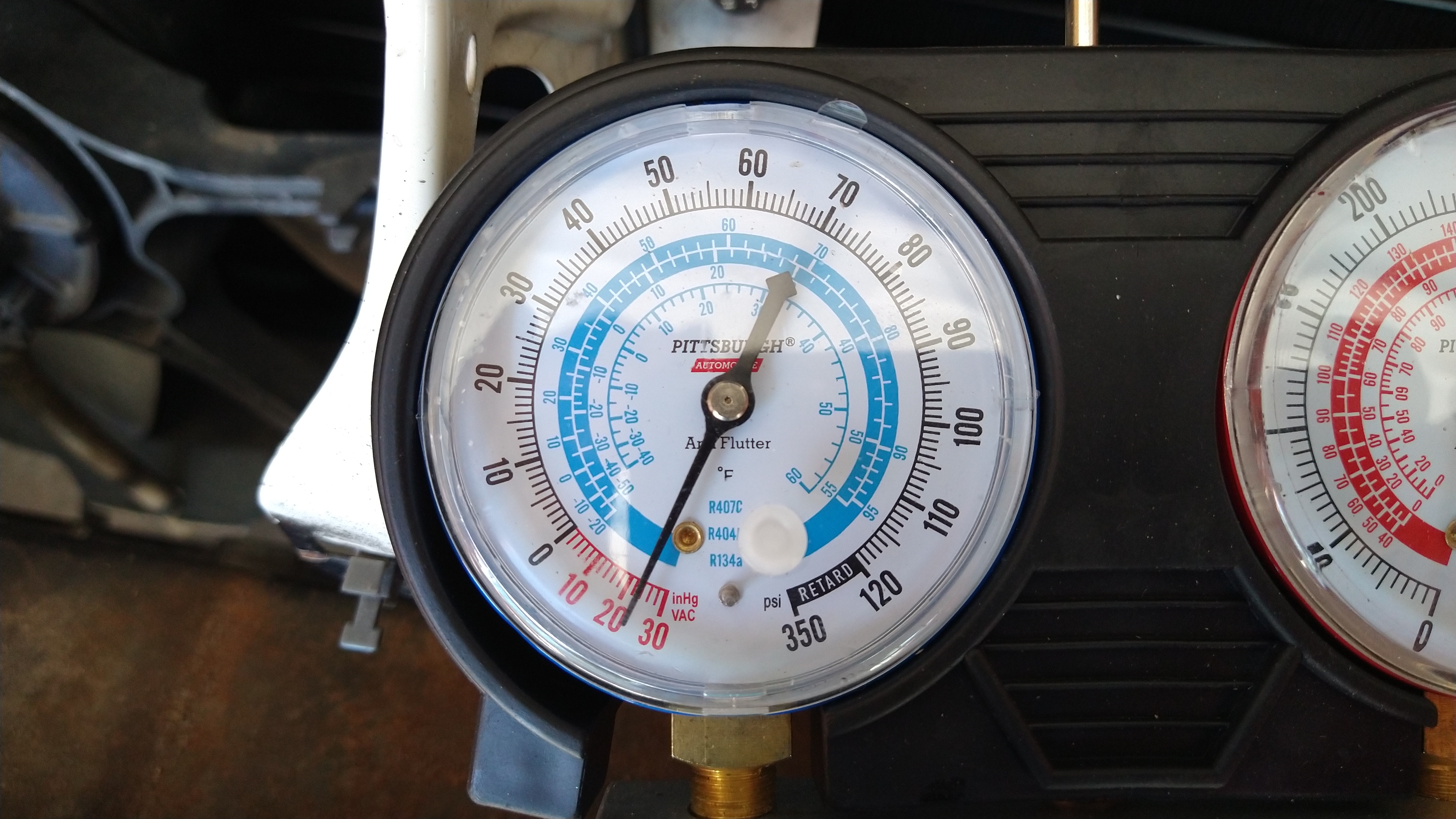

Moving on, another problem I had was the E154F's oil cooler. The stock one just...does not fit. The hard lines are too long, the soft hoses are too short, and my cooler was bent up anyway and probably will just leak. A long while ago I got a cheap tube and fin cooler I thought would possibly work...

Uh. No.

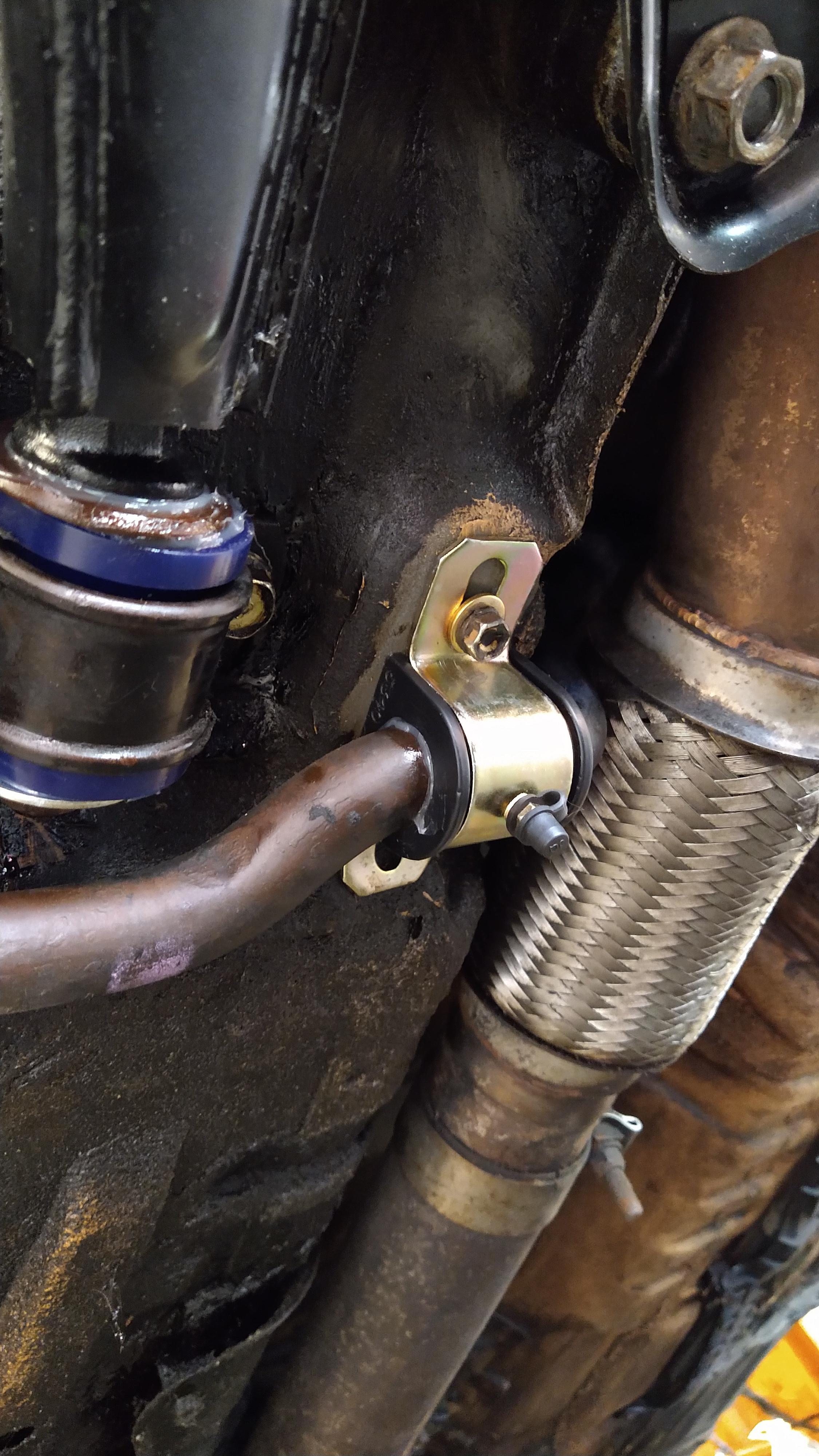

Now, there is the Wilhelm Raceworks kit. But it's for the E153 and the bracket wouldn't work on an E154F. So I did the reasonable thing and toddled off and bought the same size radiator elsewhere and got the funk out again and fabbed a full bracket for mounting it directly to the gearbox using some pre-existing holes in the case. I even routed the hoses such that the fill port is fully accessible still! Though the actual hose routing between that and my intercooler pump is a bit...tortured:

Obligatory bracket shot!

Speaking of intercooler hoses... That was a fun adventure of couplers, elbows, shipping mishaps from the UK (multiple!), and discovering the joy of heat shrink hose clamps, which made this complicated mess much easier to install:

I also built a bracket for my ST205 pump to tuck it up higher against the frame rail and kick it inboard a little bit. This allows my engine bay tray to fit over it without anything rubbing. I found if I use a tray from an automatic T16 it fits just about perfect and doesn't interfere with the trans cooler

But that, of course, is not all there is to the intercooler adventure. I'm using the stock 205 intercooler and stock 205 pump and hard pipes. Unfortunately, I could not find a way to fit the 205 intercooler radiator, so it had to go. For a while I rocked a generic unit I managed to barely cram into place, but I didn't like the results, and it gave me no room for the aircon evaporator. So after going over lots of options and crafting several intercooler radiator fitment test jig thingies, I landed upon using a 12x12x2 coolant radiator and modifying it to suit.

First order of business: Off with it's head! I didn't need the radiator cap filler, and it causes clearance issues. Lop that off, TIG up a plate over the hole, bam! Next: Its drain port faced forward. Which unfortunately makes it unusable since it would run into the bumper. So I got a down facing bung welded in and plugged the original. Got me a nice all metal petcock with a hose barb on it for slightly-less-messy coolant changes too.

Oh and more brackets. I actually reused the original radiator's upper bracket and just tapped some holes into a strip of spare steel to make an intermediary sub-bracket. The boys in Shropshire ought to be proud:

A lower bracket was fashioned as well of course. For those keeping track at home, this puts us at four brackets fabricated on our misadventure.

There was actually a fifth bracket.

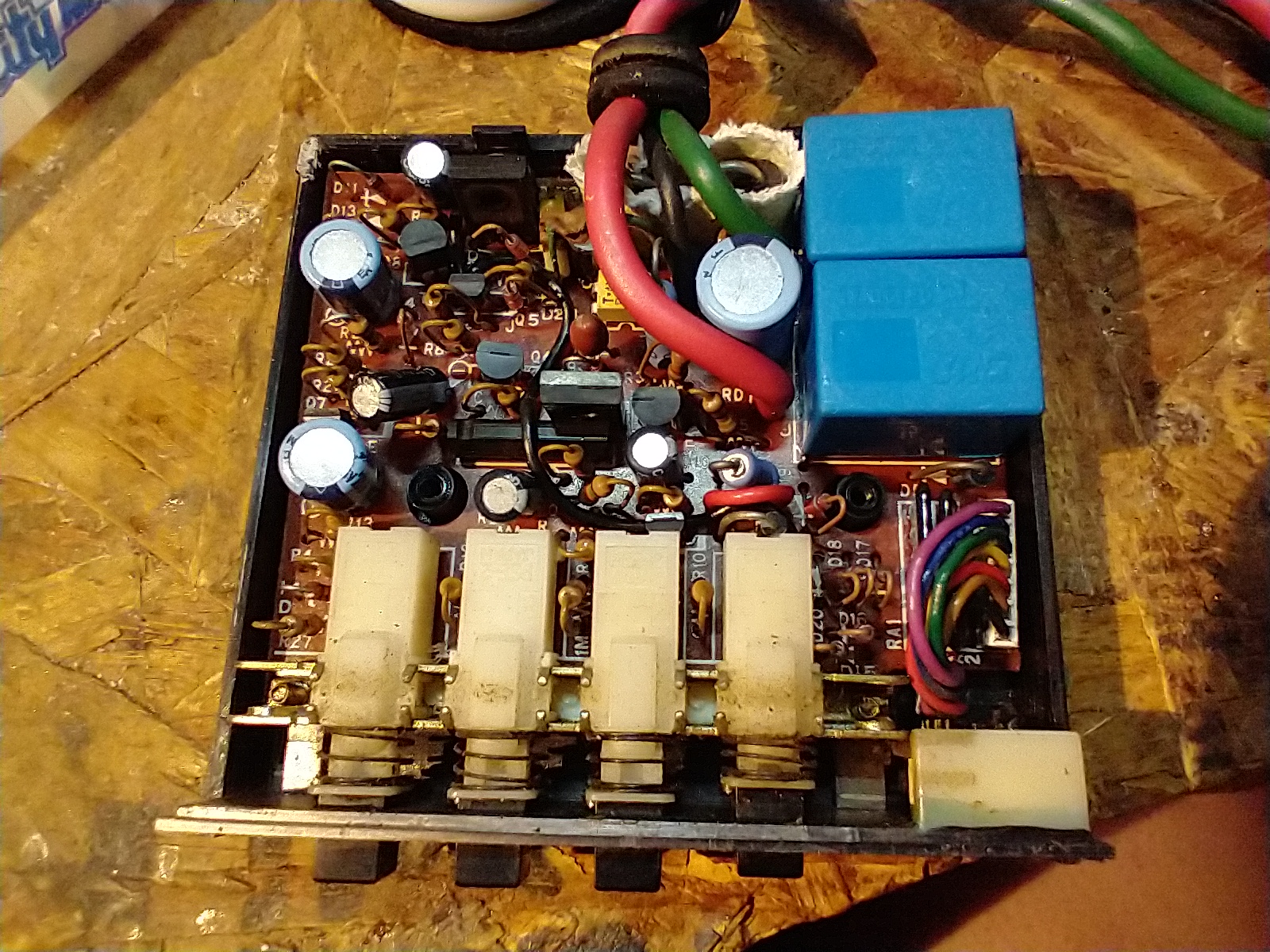

This ST165, like so many T16s and contemporary Toyotas of the time, suffers nowadays from an incontinent starter circuit. Instead of ripping apart my harnesses to run fresh copper and all that mess, I opted for the tried and true 12V Starter Mod™. I mean, I had it before but it was a janky mess. This time I went for a nice weatherproof automotive relay, weatherproof fuse holder, and proper connectors where I could to try and natively integrate the whole thing like it belonged.

This included, of course, a bracket for the relay and fuse holder. I shaped it so that it bolted up directly to the fuse box itself. That way if the fuse box needed to be moved, you simply unbolt it from the battery tie-down bracket like normal and the starter mod moves with it.

Moving on to other things that make my teeth itch: The liftback struts. Mine were dead in 2007 and have, obviously, not gotten any better. Toyota stealership ones are hilariously NLA, and everyone online for some unfathomable reason insists that the T18 liftback struts fit. ...Nein. Nyet. No. Negatory. Iie. WRONG.

First off, the T18 struts are a whopping 30 inches long. The ones for the T16 are a svelte 24 by comparison. And yes, I modifed a set of T18 struts to bolt up...they are physically too long for the liftback to even close. So no, they do not, can not, and will never ever work.

Naturally I did the reasonable thing and hunted around. A lot. Until I happened upon my MA70's old liftback struts. Funny, they're 24 inches long. But the feet are the wrong size; bolts are too close together to fit the T16. This is where I happened upon a brand where their MA70 struts have replaceable feet. Their "T16" ones do not, but the feet are the right size; they just have a permanently pressed in dowel instead of the removable one on the MA70.

My solution? Grind off and punch out the permanent dowel. Bam! The T18 Celica strut foot can now accept the serviceable dowel kit from the MA70 Supra's. Merge the two together, slap in a few washers to shim it out and I have some perfectly working liftback struts, which so long as the brand keeps making cartridges for, I can service whenever I need

MA70 strut foot in back, T16/T18 foot up front and installed. No rattles when closed even.

Some other stuff happened along the way, like swapping out a few space-shuttle-Challenger era bulbs to LEDs, swapping my blown tail light failure box for one that seems to work better, swapping the mirrors out for heated ones, slapping in some braided stainless brake hoses, getting the CT20b rebuilt with a 50-trim wheel on it, getting the rear torsen professionally rebuilt, and replacing my sunroof wholecloth because one of the cable retainers on the original just shattered. On top of I needed a new panel anyhow. But I haven't gotten to test to see if my sunroof track rebuild is successful yet as I need more shims for the panel.

She starts, purrs at idle, excellent oil pressure, all that good stuff. Now she's ready to begin engine break-in

(But still needs new tires, hah!)